Sina Auto News The second-generation Changan Yidong, which was listed at the end of March, must have left the deepest impression on everyone, which is the brand-new exterior design and the space practicality that has continued from the first-generation model. Yidong’s market vitality is very strong, and it has been firmly occupying an important market position in the independent A-class car camp for many years. In fact, there are not many independent models that can adhere to the complete life cycle and realize the replacement. For Changan, if the replacement of Yidong only stays in the face value and space, it seems a bit "strong outside and hollow inside". This time, we were lucky enough to come to Chang ‘an Automotive Engineering Research Institute to perform a major operation on the second generation Yidong to see what progress it has made compared with the first generation in terms of driving quality.

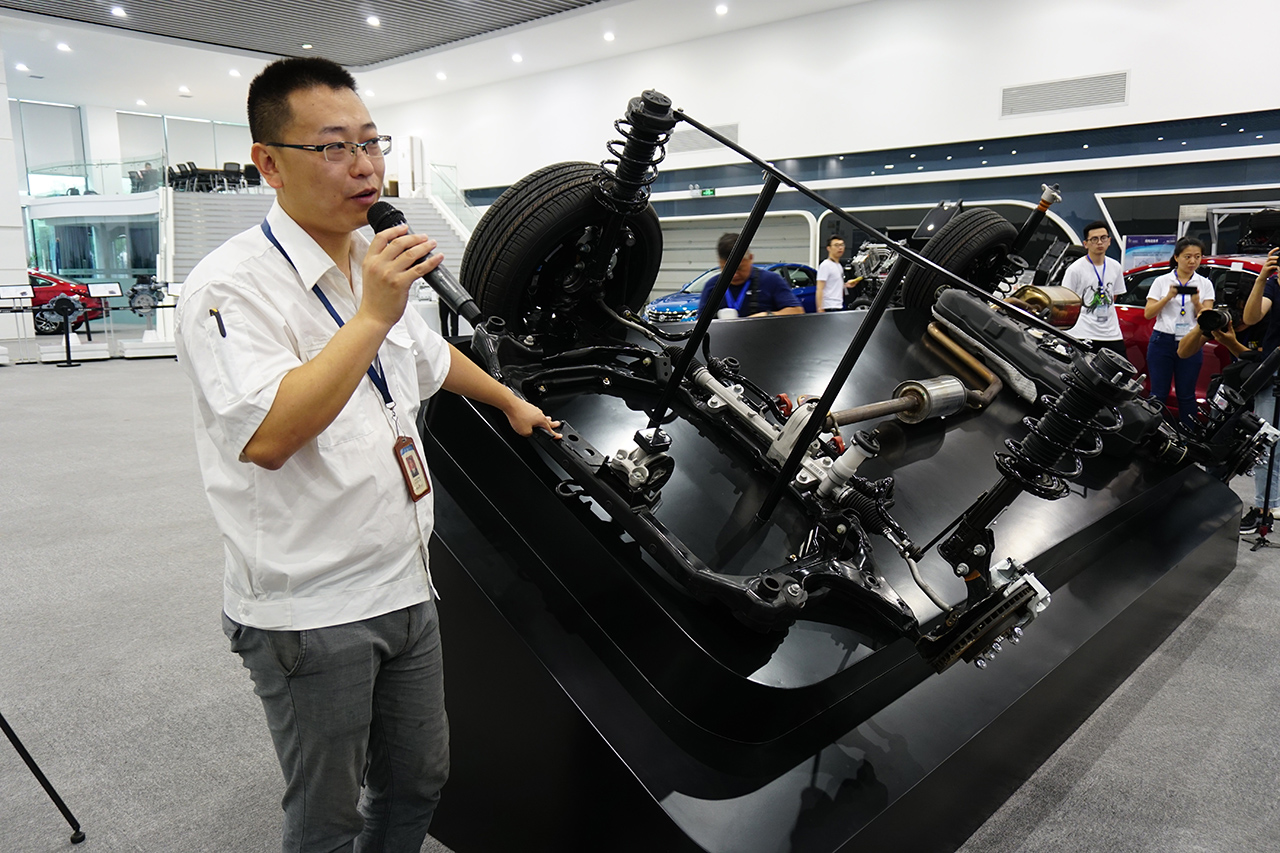

Important chassis parts of two generations of Yidong vehicles were put on the scene. Zou Yi, a senior automobile engineer in Chang ‘an, emphatically introduced the differences in suspension structure between the two generations of mobile vehicles.

Although they are all rear suspensions in the form of torsion beam, the second generation of escape rear suspension adopts U-O Forming closed torsion beam rear suspension from German suppliers, which is more difficult in process. The biggest feature of the new rear suspension is that it reduces the weight by 20% compared with the traditional V-shaped torsion beam on the basis of ensuring the structural strength. The reduction of unsprung weight has obvious benefits for vehicle handling performance.

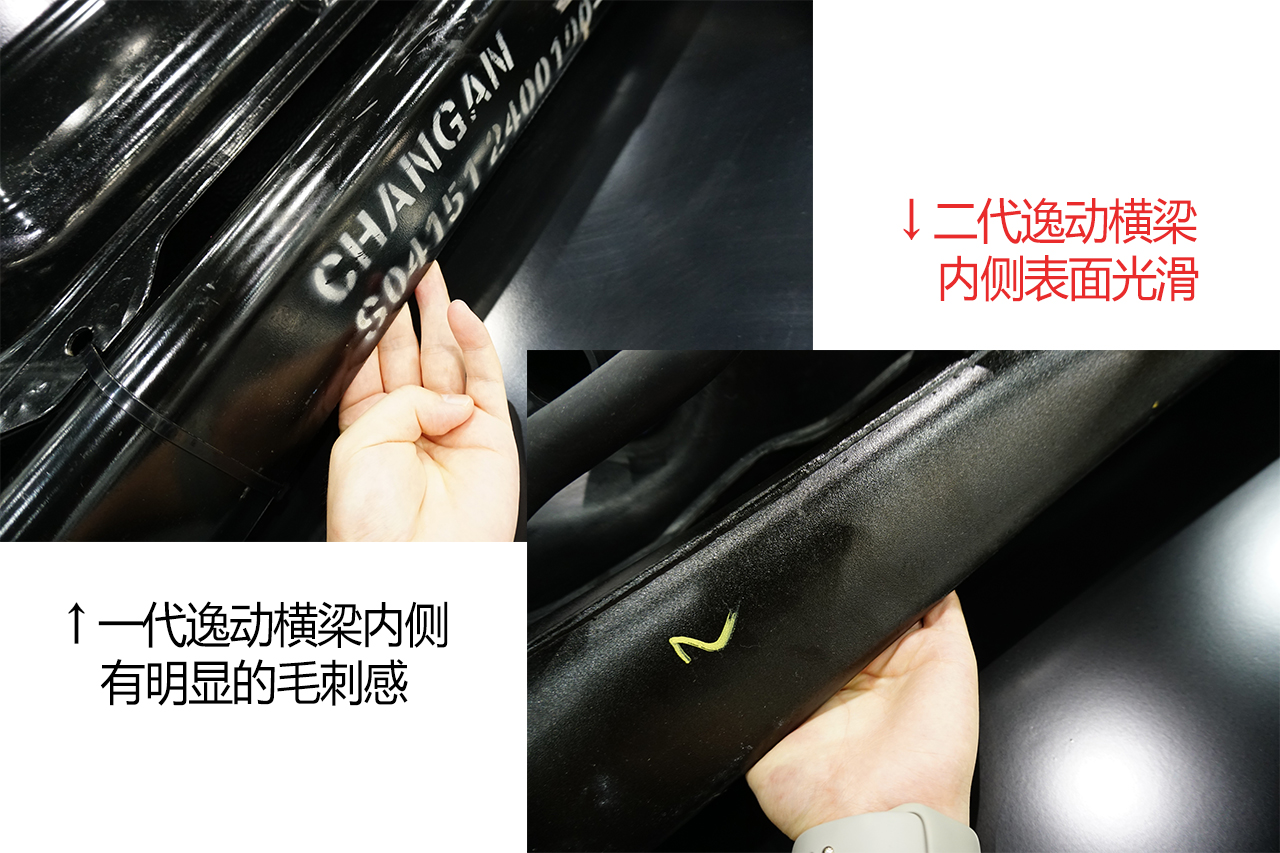

The improvement in technology is perceptible. Touching the inner side of the cross beam of the two-generation mobile rear suspension, you will find that the inner surface of the first-generation runaway has obvious burr feeling, while the inner side of the second-generation vehicle is obviously smoother, which feels like the effect after a steel plate is bent and butted end to end.

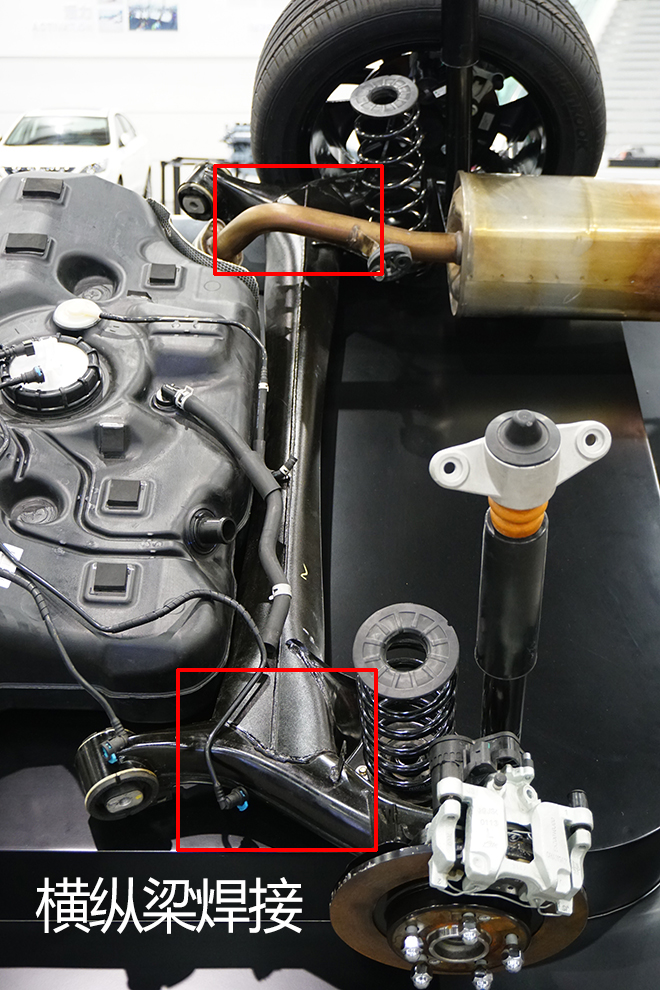

Facing the domestic road conditions, the hidden danger of the rear suspension of many models is not the fracture of the cross beam, but the stress fatigue is easy to form between the transverse and longitudinal beams. The welding area between the second-generation escape rear suspension beam and the longitudinal beam has been increased, and the official introduction shows that its reliability has been improved by 380%.

There are also differences in the arrangement of rear suspension shock absorbers between the two generations. We see that the shock absorber of the first generation model is located in front of the shock absorber spring and has a short length; The shock absorber of the second generation model is located behind the spring and has a long length. The purpose of adopting this vertical arrangement is to improve the efficiency of isolating vibration. After all, a longer shock absorber can provide a larger compression stroke and more adjustment space, thus improving the comfort of the rear row. In fact, if you pay attention, you will find that many luxury brands C-class cars and D-class cars also use this "super-long" shock absorber and arrangement. At present, this layout method has been used in Focus, Lectra 01 and other models, and the next generation of GM models will be equipped. Independent brands have also been gradually adopted, and the second generation of Yidong is one of them.

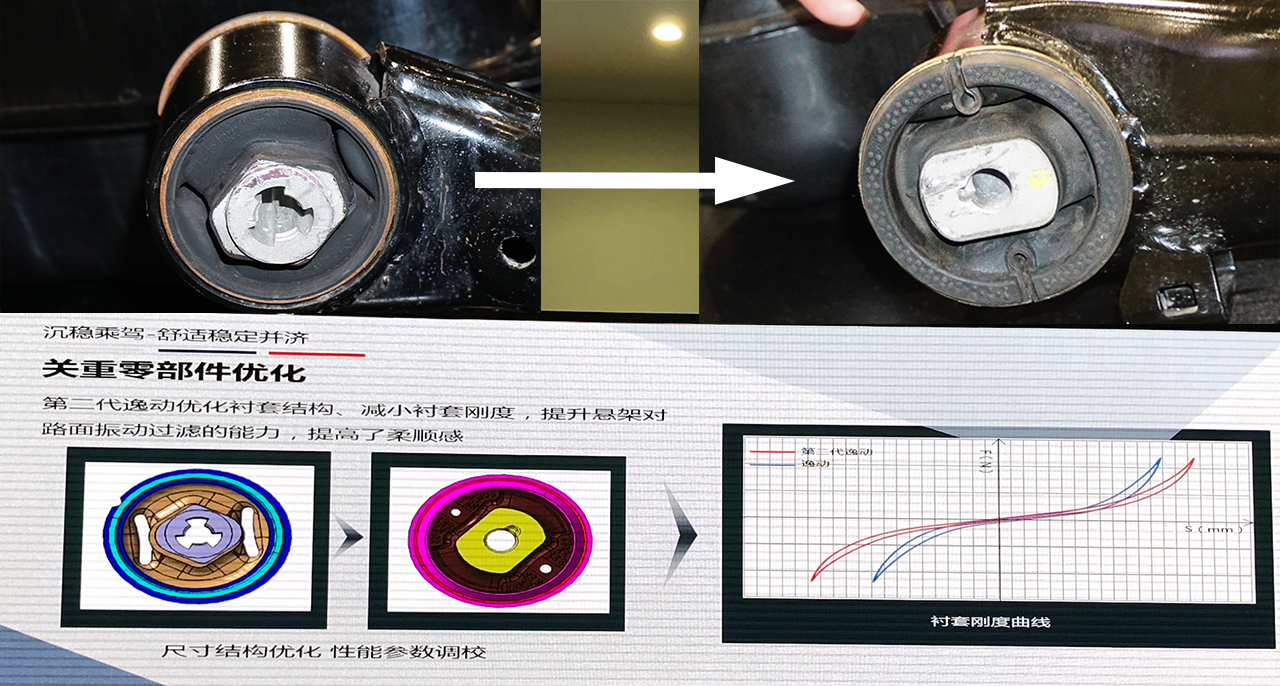

In order to improve the comfort, engineers have also optimized the bushing structure of the second-generation runaway suspension, and appropriately reduced the stiffness of the bushing, which can improve the filtering ability of the suspension to road vibration and help to isolate the road from fine bumps.

Changan engineer also demonstrated the process of adjusting the shock absorber for us. Engineers will put the designed shock absorber prototype on the bench for testing, and the bench will compress/expand the shock absorber at different speeds of 0.05, 0.1, 0.3, 0.6 and 1.2m/s for four times to simulate the daily road conditions. In this process, the system will generate the damping data of the shock absorber to optimize the shock absorber repeatedly. We see that there are throttle plates with different sizes and shapes in the shock absorber, each with different specifications.

For example, there are 28 different schemes of throttle plate in the above picture, and its working state and deformation can affect the flow of damping oil, and then affect the performance of shock absorber. Although the shock absorber does not directly reflect the "soft and hard" parts of a car suspension, these small differences can determine the final driving experience of a car. In fact, few domestic independent brands can independently develop, test and adjust shock absorbers like Changan, and most of them directly send the requirements to suppliers for them to do.

After the chassis suspension is developed, the vehicle will be handed over to KC test bench to verify the suspension and steering motion characteristics. The cost of the test-bed is about 20 million yuan, which can quantitatively simulate the load and wheel state parameters of the suspension under various road conditions or body postures. It takes 2 days for each prototype to be put on the shelf, collect data, and then complete a set of tests, in which the collection time of complete KC data takes 4 hours. Of course, it is impossible for a car to go through KC test only once, and the comprehensive performance of the chassis system needs to be adjusted and verified repeatedly. This process is extremely cumbersome.

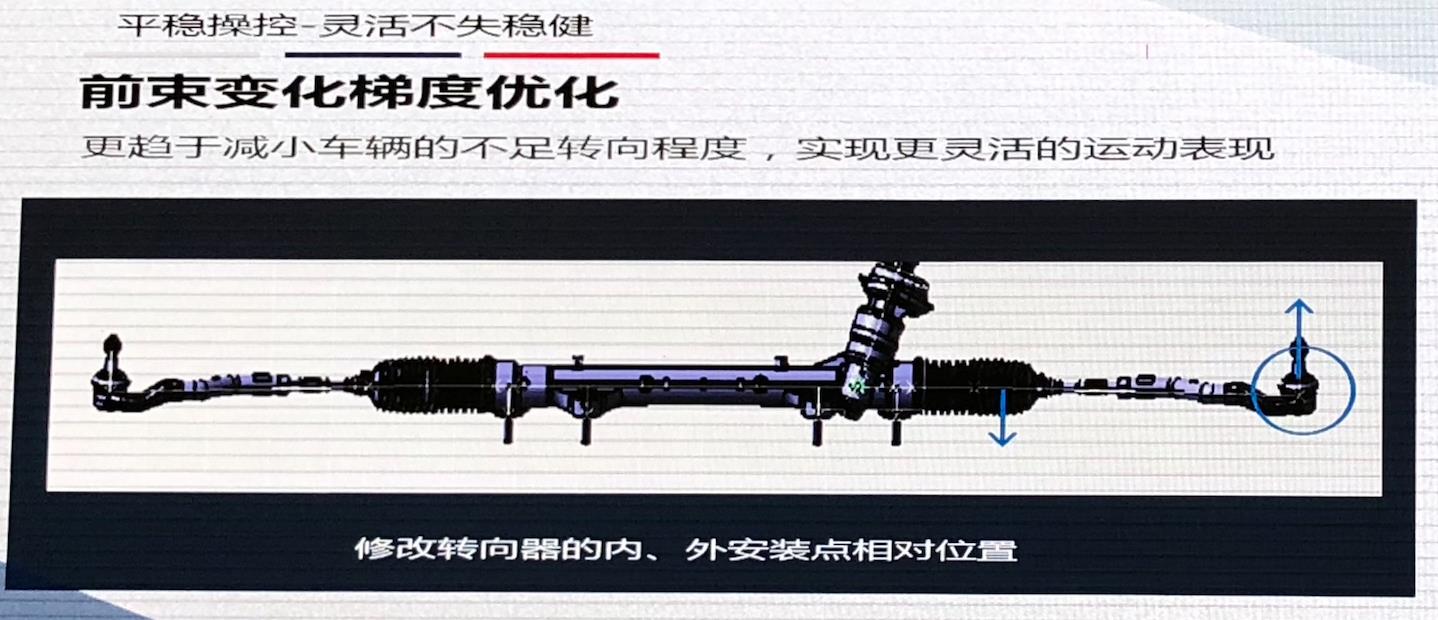

For front-drive vehicles, vehicles tend to understeer during intense driving. It is impossible for a car to have no understeer at all, and engineers can only minimize this trend. In the second generation, the toe-in gradient of the wheel was optimized, and the relative positions of the internal and external mounting points of the steering gear were modified, which can slow down the trend of understeer to a certain extent, and then improve the handling stability of the vehicle in corners.

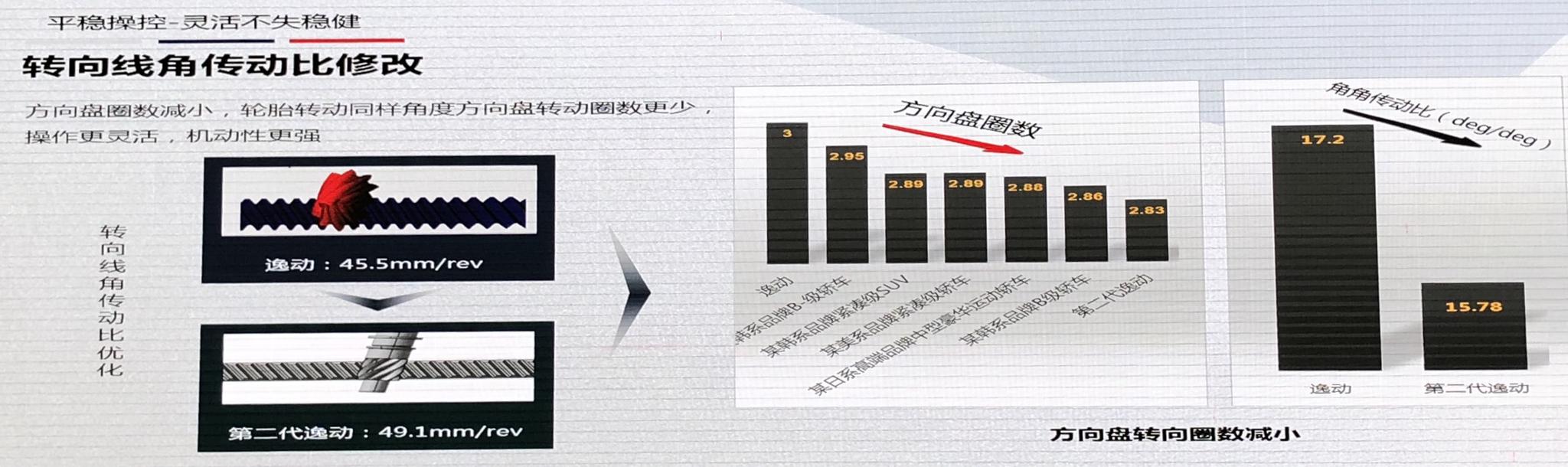

Chang ‘an has his own thoughts on driving DNA. For example, in terms of steering transmission ratio, the second generation of escape has not only pursued the feeling of comfort. Compared with the first generation model, its steering line angular transmission ratio is reduced from 3 laps to 2.83 laps. Most cars and SUV models on the market need about 2.8~3 laps from left to right, and sports-oriented models will take about 2.5 laps. From the change of the transmission ratio of the second-generation freewheeling steering, we can also see that Chang ‘an is not satisfied with "good driving", but should work hard in the direction of "fun+good driving".

For the adjustment of EPS electric power steering carried by the second generation Yidong, Changan uses a set of "robot" system that can quantitatively control the steering wheel angle and speed, and measure the steering wheel torque and body roll angle in real time. Engineers will set up different test forms, such as sine input, sweeping and catching up, to test the roll degree of the vehicle, the response speed of the steering wheel and the reliability of the steering motor respectively. It is worth mentioning that the second generation of escape has improved the power of EPS steering assist motor, so that the ease of use and reliability of the vehicle in extreme handling are more guaranteed.

In addition to the steering transmission ratio just mentioned, the steering force feel is also an important item in EPS adjustment. Engineers showed us two different forces used in the test, namely, extremely light and heavy. During the test drive, you can really feel the different performances of the vehicle under two kinds of dynamics. In the extremely light mode, the steering feel of the vehicle is almost zero, and it begins to respond when it touches the vehicle lightly; In the heavier mode, the steering power is obviously reduced, and the arm will be tired when rubbing the car and turning around at low speed. The engineer said that the steering power directly affects the communication between a car and the driver, and it is not advisable for the steering wheel to be too light or too heavy. Therefore, EPS should be adjusted in combination with factors such as vehicle positioning and suspension calibration, so as to achieve stability and give people some driving pleasure.

In April this year, the second generation Yidong achieved a braking performance of 35.6 meters in a public test, which is known to friends who know a little about cars-similar to many luxury brand sports-oriented models. This time, Changan engineers analyzed some reasons behind this achievement for us.

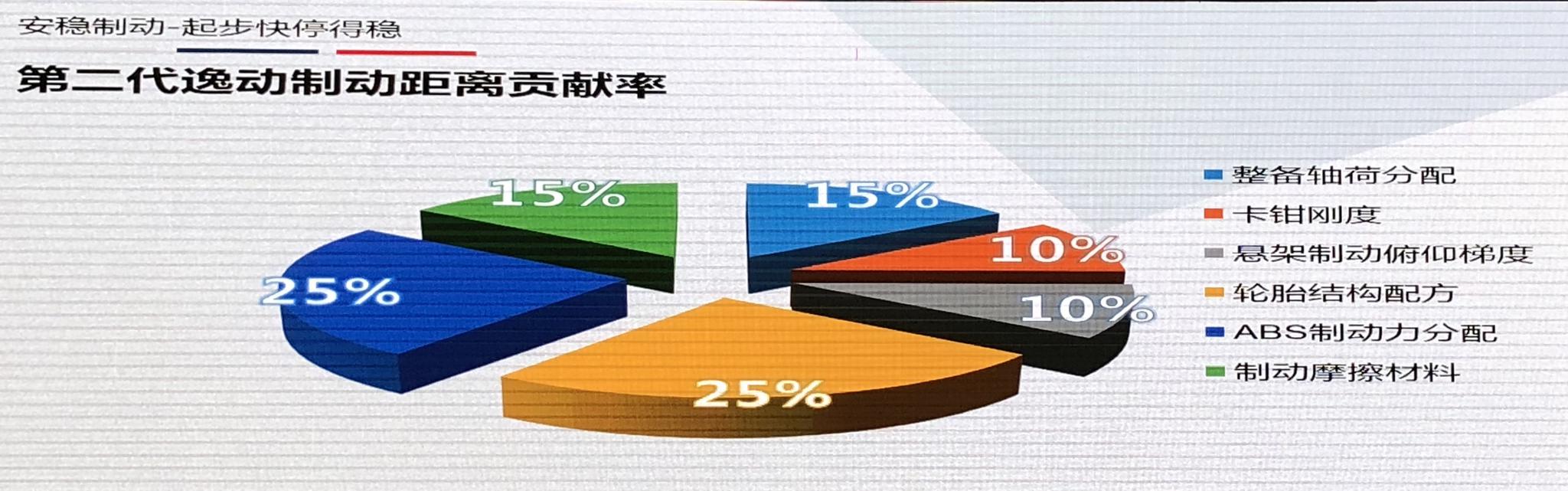

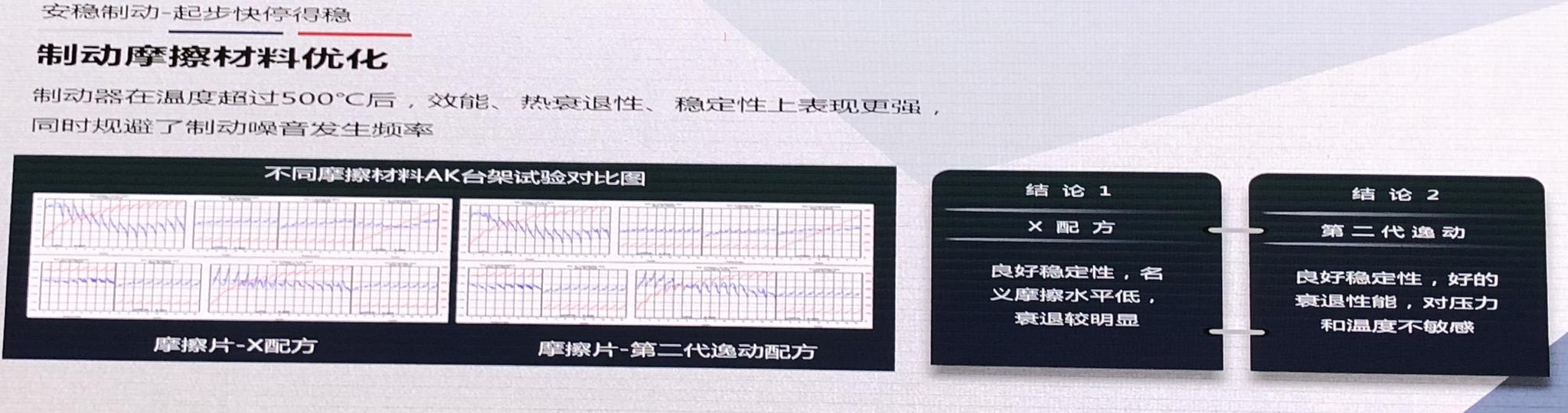

In this pie chart, we can see that the braking performance of a car excludes environmental factors, and the factors related to the vehicle itself include axle load, calipers, body posture, tires, ABS and friction materials. The second generation of escape is mainly optimized for the thermal stability of the brake system and the formula of the brake shoe.

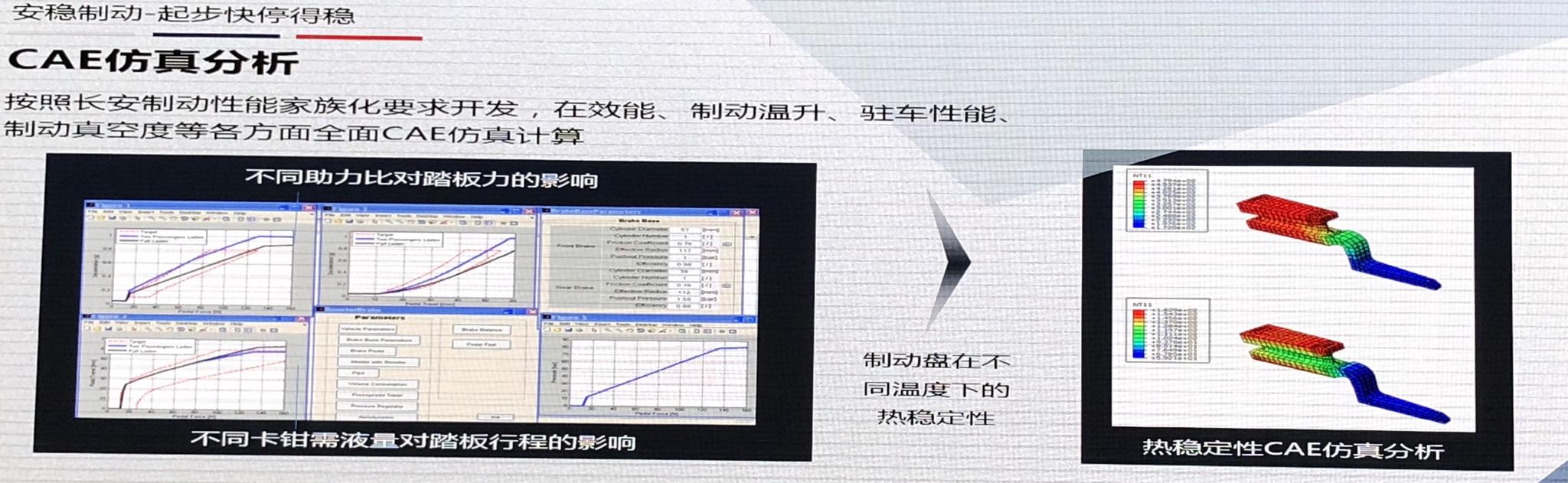

Through CAE simulation analysis, the influence of different caliper fluid requirements on pedal stroke is simulated, and then the thermal stability of brake disc at different temperatures is simulated. Simulation analysis can greatly improve the efficiency of research and development, so that engineers can take as few detours as possible.

Of course, only simulation analysis is not enough. Chang ‘an also has its own braking system laboratory. For example, this is where the brake pedal strength and master cylinder pressure are tested. Why are the brake pedals of some models "soft" at the initial stage, and it is necessary to step on the vehicle deeply before the braking force is obviously released? This is the key issue. Generally speaking, there is a certain gap between the pedal and the master cylinder pressure, that is, the empty position of the brake pedal, but excessive defecation in the empty position will delay the release of braking force and even cause safety hazards. Although the second-generation Yidong 35.6-meter 100-kilometer braking performance is not directly related to fine adjustment, we can also see from here that Changan’s control over the details of driving experience is quite in place.

In terms of braking materials, the second generation Yidong has optimized the formula compared with the previous generation. The main improvement aspect is to control the thermal decay of the brake as much as possible when it is above 500℃, and reduce the sensitivity of the brake to pressure and temperature. In other words, in the future, car owners can use the brake pedal to control the speed more confidently when they are driving downhill on a mountain road for a long time, and the vehicle is not easy to "stop" because the temperature of the brake system is too high.

In the past, independent brands were still making efforts in terms of large space and high configuration, striving to win the favor of consumers with low prices and high allocation. With the domestic auto market becoming more and more mature, the car buyers have a deeper understanding of cars, and improving the internal quality of vehicles has become a hard bone that manufacturers have to chew. Two generations of Yidong, the first generation of models gain a foothold with high cost performance, and the second generation of models will inevitably improve their driving quality. You really can’t just look at the configuration list when buying a car in the future. If you don’t get in the car and drive it, it’s hard for you to know its inner beauty.